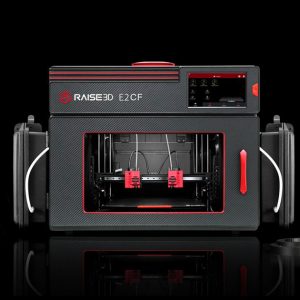

Raise 3D E2CF

Kohlenstofffaser-3D-Druck leicht gemacht.

Der E2CF ist ein Desktop-3D-Drucker, der von Raise3D für kohlenstofffaserverstärkte Filamente und andere Verbundmaterialien entwickelt wurde.

Luft- & Raumfahrt

Architektur

Automobilindustrie

Handelsgüter

Bildungswesen

Medizin

Double-Gear Extrusion System

Die Zahnräder bestehen aus hochfestem Stahl und wurden wärmebehandelt, um eine höhere Widerstandsfähigkeit gegen Abnutzung zu gewährleisten. Das Zahnradprofil ist individuell angepasst, und die Doppelzahnräder greifen beim Betrieb fest ineinander, sodass es beim Extrudieren zu keinem Filamentrutschen kommt. Die Kraft des Doppelt-Zahnrads wird verdoppelt, um die Stabilität des Drucks sicherzustellen.

1,75 mm

Filamentdurchmesser

300°C

Extruder Temperatur

30–150 mm/s

Druckgeschwindigkeit

330 x 240 x 240 mm

Druckvolumen

Nozzle with langer Beständigkeit

Die Düse aus Siliziumkarbid bietet ausgezeichnete Wärmeleitfähigkeit und Abriebfestigkeit, wodurch die Abnutzung, die das kohlenstofffaserverstärkte Verbundfilament beim Drucken an der Düse verursacht, erheblich reduziert wird. Dies macht die Düse langlebiger.

Kompatibel mit verschiedenen Kohlenstofffaser-Verbundfilamenten

Der E2CF ist kompatibel mit dem Raise3D Industrial PA12 CF Filament und auch sehr gut geeignet für leistungsstarke Kohlenstofffaserfilamente, die vom Raise3D OFP-Programm zertifiziert sind, wie PA / PPS / PETG sowie einige andere leistungsstarke Kohlenstofffaser-Verbundfilamente von BASF und LEHVOSS.

Raise3D Filament Dry Box

Das integrierte, abnehmbare Doppelscheiben-Aufhängetablett dient dazu, das Filament so zu platzieren, dass das Material gleichmäßiger abgezogen werden kann. Bei geschlossener Box kann es effektiv Staub und Feuchtigkeit für bis zu 30 Tage* verhindern. *Basierend auf Testdaten von Raise3D.

Exklusive ideaMaker Slicing Profile

Der E2CF verfügt über exklusive Slicing-Profile, die von unseren Ingenieuren in ideaMaker wiederholt getestet und verifiziert wurden. Es ist keine Anpassung der Parameter vor dem Drucken erforderlich. Genießen Sie einfaches und qualitativ hochwertiges Drucken.

Materialien für Raise 3D E2CF

Raise 3D E2CF Webinar

Damit Sie mit Ihrem neuen 3D-Drucker schnell produktiv arbeiten können, bieten wir Ihnen unseren Schnellstart-Kurs in Form eines Webinars (Web-basiertes Seminar) an: Nach 120 Minuten verstehen Sie die Funktionsweise der 3D-Drucksoftware.

Ablauf des Webinars

- Einführung in die Funktionsweise und Bedienung der 3D-Drucksoftware

- Überblick über die Bedeutung der Einstellungen

- Die richtigen Einstellungen für Ihren perfekten 3D Ausdruck!

- Tipps & Tricks

- Trouble Shooting – Ursachen und Lösungen für die häufigsten Probleme

Voraussetzungen

- Vorhandener, einsatzbereiter PC mit Windows 7, 8 oder Mac OS X mit vollen Administrator-Rechten

- Internetzugang

- Bereits installierte und funktionsbereite TeamViewer oder Microsoft Teams Software

Die Details zum Termin und der Webinar-Software werden nach Eingang Ihrer Bestellung abgesprochen.

Support und Service

- Professionelle Beratung

- Musterdruck Erstellung

- Individuelle Pakete für Industriekunden

- Einschulung vor Ort

- Servicepaket mit kostenlosem Telefon- und Email Support

- Gesamtlösung mit Waschstation

- Bauteiloptimierung via Fernwartung

- Materialversuche

- Prozessoptimierungen

- Kundenspezifische Seminare vor Ort

- Vor Ort Service

Downloads

Technische Daten

| Build Volume (WxDxH) | Single Extruder Print: 330×240×240 mm Dual Extruder Print: 295×240×240 mm |

| Machine Size (WxDxH) | 607×596×465 mm |

| Power Supply Input | 100-240 V AC, 50/60Hz 230 V @ 2A |

| Power Supply Output | 24 V DC, 350 W |

| Print Technology | FFF |

| Print Head System | IDEX Independent Dual Extruders |

| Filament Diameter | 1.75 mm |

| XYZ Step Size | 0.78125, 0.78125, 0.078125 micron |

| Print Head Travel Speed | 30 – 150 mm/s |

| Build Plate | Flexible Steel Plate with Buildtak |

| Max Build Plate Temperature | 110 ºC |

| Heated Bed Material | Silicone |

| Build Plate Leveling | Mesh-leveling with Flatness Detection |

| Filament Run-out Sensor | Available |

| Supported Materials | PA12 CF, PA12 CF Support, OFP Certified Third-Party Filaments |

| Layer Height | 0.1 – 0.25mm |

| Nozzle Diameter | 0.4 mm (Default), 0.6/ 0.8 mm (Available) |

| Hotend | V4P |

| Max Nozzle Temperature | 300 ºC |

| Connectivity | Wi-Fi, LAN, USB port, Live camera |

| Noise Emission (Acoustic) | <50 dB(A) when building |

| Operating Ambient Temperature | 15 – 30 °C, 10 – 90% RH non-condensing |

| Storage Temperature | -25 °C to +55 °C, 10 – 90% RH non-condensing |

| Filter | HEPA filter with activated charcoal |

| Slicing Software | ideaMaker |

| Supported File Types | STL/ OBJ/ 3MF/ OLTP |

| Supported OS | WINDOWS/ macOS/ LINUX |

| Machine Code Type | GCODE |

| User Interface | 7-inch Touch Screen |

| Network | Wi-Fi, Ethernet |

| Power Loss Recovery | Available |

| Screen Resolution | 1024*600 |

| Motion Controller | Atmel ARM Cortex-M4 120MHZ FPU |

| Logic Controller | NXP ARM Cortex-A9 Quard 1 GHz |

| Memory | 1 GB |

| Onboard Flash | 8 GB |