Eplus3D EP-M300

Metal Additive Manufacturing: hoch produktiv & verlässlich

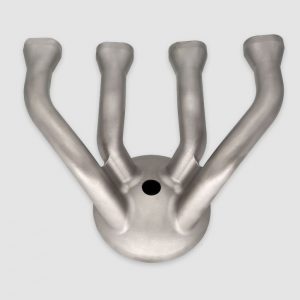

Medizin

Automobilindustrie

Luft- & Raumfahrt

Handelsgüter

Energie

Architektur

Prototypen

Hoch effizient

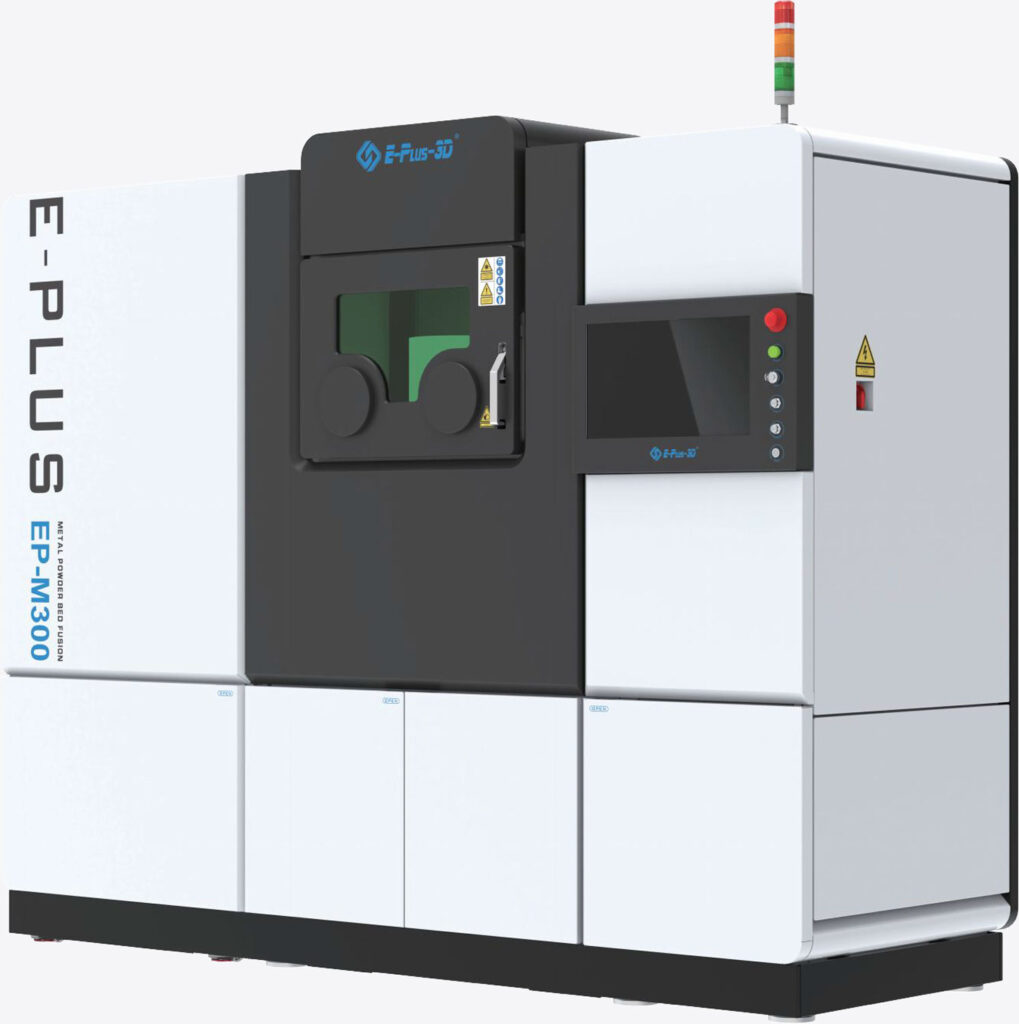

Die Bauraumgröße beträgt 300 x 300 x 450 mm (Höhe abzüglich Substratplatte). Durch Vergrößerung der Schichtdicke wird eine hohe Ausbringung gewährleistet. Durch die eigens entwickelte Prozesssoftware EP-Hatch, werden optimierte Scan Strategien erstellt, welche zu reduzierten Druckzeiten führen.

bis 95 cm³/h

Baugeschwindigkeit

20 μm – 120 μm

Schichtdicke

300 x 300 x 450 mm

Druckvolumen

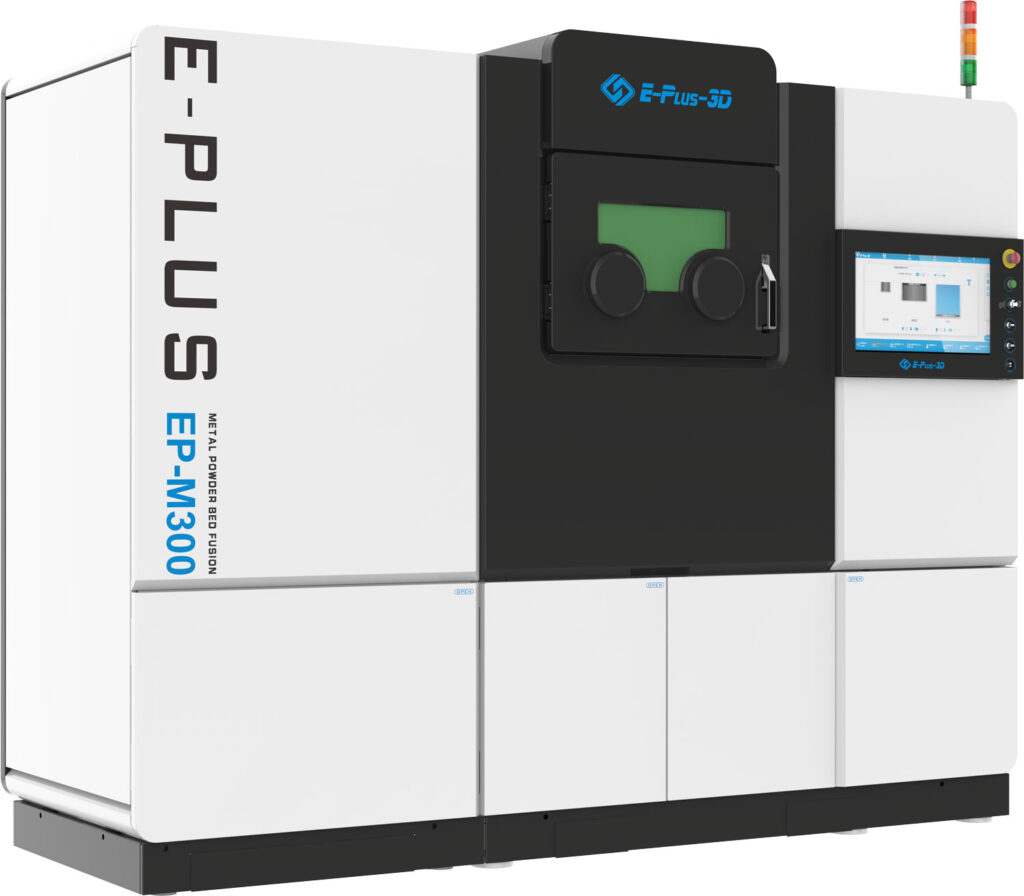

Optimiertes Design

Ein großer Bauraum mit Single- oder Duallaserkonfiguration sind möglich. Benutzerfreundlichkeit und ein dreistufiges, selbstreinigendes Filtersystem sorgen für. Verschiedene, auf die Anwendung angepasste Beschichtersysteme möglich.

Offenes System

Offene Parametersätze zur Möglichkeit der Optimierung von Laserleistung, Scangeschwindigkeit und weiteren 200+ Parametern um die Fertigung von Bauteilen in der Serie zu optimieren. Das offene System ermöglicht es, frei zwischen den verfügbaren Metallpulvern auf dem Markt zu wählen. Eine Vielzahl von Materialparameterpaketen herstellerseitig verfügbar.

Hohe Qualität

Hohe Dichte von > 99,95 % und eine geringe Eigenschaftstoleranz der gedruckten Objekte. Der optimierte Gasstrommanagement sorgt für eine effiziente Entfernung von Schweißrauch und Spritzern und dem Erreichen von beständigen und konstanten Druckergebnissen. Die Drucksoftware bietet die Möglichkeit, Modelle in verschiedene Abschnitte zu unterteilen.

Zuverlässig & Sicher

Hervorragende optische Kernkomponenten von Weltklasse-Lieferanten und ausgereiften Prozesskontrollparameteralgorithmen sorgen für höchste Teilequalität. Gleichmäßiger Teiledruck in hoher Qualität durch exzellente Überwachung über den Bauteilaufbau, der Umgebung und anderer Komponenten. Das Passivierungssystem des Filters für aktive Materialien wie Aluminium und Titan erhöht die Bedienersicherheit drastisch. Die Glovebox ermöglicht das Auspacken der Bauteile ohne die Tür zu öffnen.

Kosteneffektiv & einfach zu bedienen

Blowback-Funktion ermöglicht bis zu 1500 Betriebsstunden des Filtersystems. Permanentfiltersystem optional. Sehr bedienerfreundliche Softwareoberfläche mit One-Click-Printing Technologie erleichtert die Druckvorbereitung. Geringe Betriebskosten durch reduzierten Gasverbrauch von ≤ 6 L/min während des Druckvorgangs.

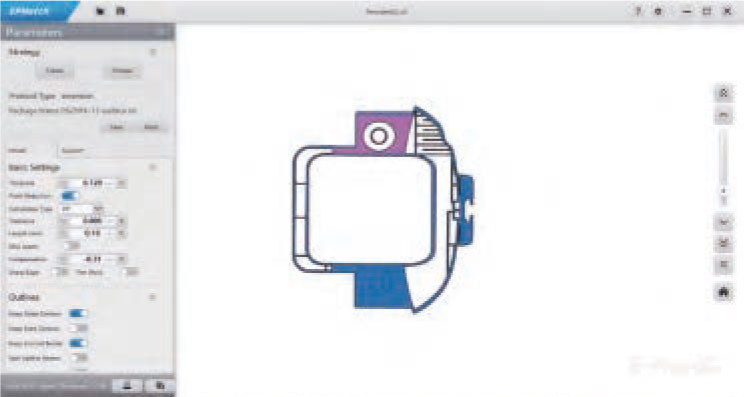

Eplus3D Softwarelösungen

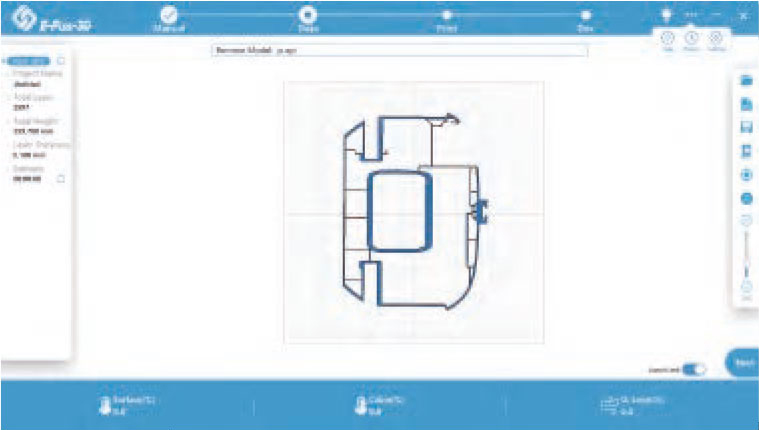

EP-Hatch Druckprozess-Planungssoftware

EP-Hatch ist eine von Eplus3D entwickelte Prozessplanungssoftware speziell für seine additiven Fertigungssysteme. Sie kann den Druckpfad basierend auf den bereits geschnittenen und ausgegebenen Daten optimieren und den Scanpfad separat für Kontur, Inneres, obere und untere Oberfläche des Teils einstellen. Darüber hinaus bietet EP-Hatch standardmäßig eine Vielzahl fortschrittlicher Scanstrategien wie lange gerade Linien, kurze gerade Linien, und Schachbrettmuster, die eine optimale Prozesseinstellung für spezifische Materialien ermöglichen.

EPlus3D Steuersoftware

Die von Eplus3D entwickelte Steuersoftware repräsentiert ein leistungsstarkes Steuersystem. Mit einer offenen und benutzerfreundlichen Schnittstelle ermöglicht sie den Benutzern, ihre digitalen Dateien von der Bauvorbereitung und Teilepositionierung einfach zu steuern und bietet zudem die Möglichkeit zur Überwachung während des Bauprozesses samt Berichterstellung. Das kraftvolle Steuer- und Betriebssystem unterstützt nicht nur den Druck von ausgereiften Materialien, sondern auch die Entwicklung neuer Materialien.

Eplus3D EP-M300 Support und Service

- Professionelle Beratung

- Musterdruck Erstellung

- Individuelle Pakete für Industriekunden

- Einschulung vor Ort

- Individuelle Servicepakete

- Gesamtlösung mit geschlossener Entpulverstation

- Bauteiloptimierung via Fernwartung

- Materialversuche

- Prozessoptimierungen

- Kundenspezifische Seminare vor Ort

- Vor Ort Service

Downloads

Technische Daten

| Maschinenmodell | EP-M300 |

| Bauraum (L x B x H) (Höhe abzüglich Substratplatte) | 300 x 300 x 450 mm |

| Optisches System | Faserlaser, 500 / 1000 W (Single- oder Duallaser) |

| Laserspotgröße | 70 - 120 μm |

| Max. Scangeschwindigkeit | 8 m/s |

| Theoretische Druckgeschwindigkeit | Bis 95 cm³/h |

| Schichtdicke | 20 μm - 120 μm |

| Material | Titan-, Aluminium-, Nickelbasis, Cobalt-Chromlegierungen sowie Werkzeug- und Edelstähle, etc. |

| Stromversorgung | 380 V, 31 A, 50 / 60 Hz, 7 kW |

| Gasversorgung | Ar/N2 |

| Sauerstoffgehalt in Prozesskammer | ≤100 ppm |

| Dimensionen (L x B x H) | 2990 x 1320 x 2590 mm |

| Gewicht | 2900 kg |

| Software | EPControl, EPHatch |

| Format Eingangsdaten | STL oder andere konvertierbare Formate |