Eplus3D EP-P420

Polymer SLS-Drucker

Medizin

Automobilindustrie

Luft- & Raumfahrt

Handelsgüter

Energie

Architektur

Prototypen

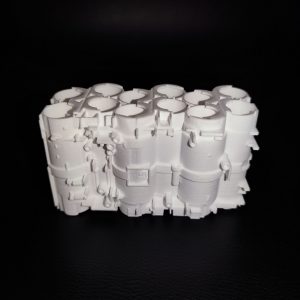

Hohe Leistungsfähigkeit und Effizienz

Diskrete Variation der mechanischen Eigenschaften bleibt beim Druck von Teilen in voller Größe unter 5%. Mit 120 W Laserleistung bietet die Maschine eine höhere Druckgeschwindigkeit. Hohe Material-Wiederverwendungsrate: Frisches Pulver macht nur 20% der Erneuerungsrate aus.

2500 cm3/h

Baugeschwindigkeit

0,06 – 0,2 mm

Schichtdicke

420 x 420 x 465 mm

Druckvolumen

Echtzeit-Temperatur-Management-System

Optimiertes Echtzeit-Temperatur-Management-System mit einer Temperaturfeldschwankung von nur ≤ ±1,0°C.

optische Scanpfadstrategie

Fortschrittliche optische Scanpfadstrategie sichert herausragende Details und eine exzellente Oberflächenqualität.

Hohe Material-Wiederverwendungsrate

Einzigartiges kein-Restmaterial-Design verbessert die Pulvernutzungsrate. Frisches Pulver macht nur 20% der Erneuerungsrate aus.

Offene Druckparameter

Offene Druckparameter ermöglichen die Entwicklung neuer Materialien.

230°C Bautemperatur

Bautemperatur von bis zu 230°C ermöglicht die Verarbeitung einer breiteren Palette von Polymeren.

Großvolumiger Pulverspender

Eine Füllung reicht für den gesamten Zylinderdruck.

Abnehmbares Schutzfenster

Abnehmbare optische Schutzfenster erleichtern die tägliche Wartung.

Benutzerfreundlich

Scanpfadgenerierung mit einem Klick. Druckfähig mit einem Klick.

Intelligent

Automatische Generierung eines Druckberichts, um den Druckprozess zu verfolgen. Automatische Störungsbehandlung, vermeidet Schäden an der Ausrüstung.

Eplus3D Softwarelösungen

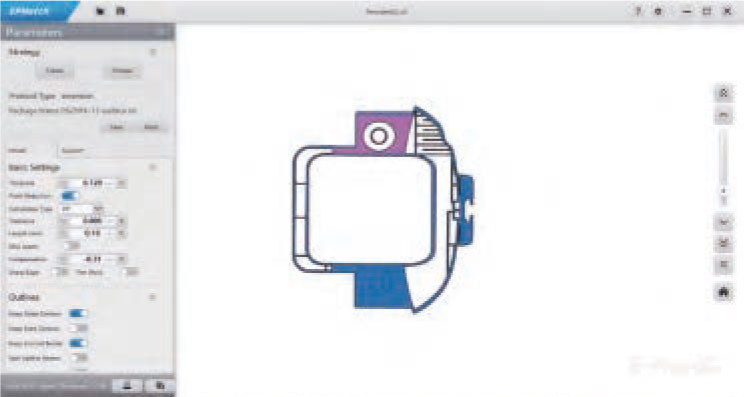

EP-Hatch Druckprozess-Planungssoftware

EP-Hatch ist eine von Eplus3D entwickelte Prozessplanungssoftware speziell für seine additiven Fertigungssysteme. Sie kann den Druckpfad basierend auf den bereits geschnittenen und ausgegebenen Daten optimieren und den Scanpfad separat für Kontur, Inneres, obere und untere Oberfläche des Teils einstellen. Darüber hinaus bietet EP-Hatch standardmäßig eine Vielzahl fortschrittlicher Scanstrategien wie lange gerade Linien, kurze gerade Linien, und Schachbrettmuster, die eine optimale Prozesseinstellung für spezifische Materialien ermöglichen.

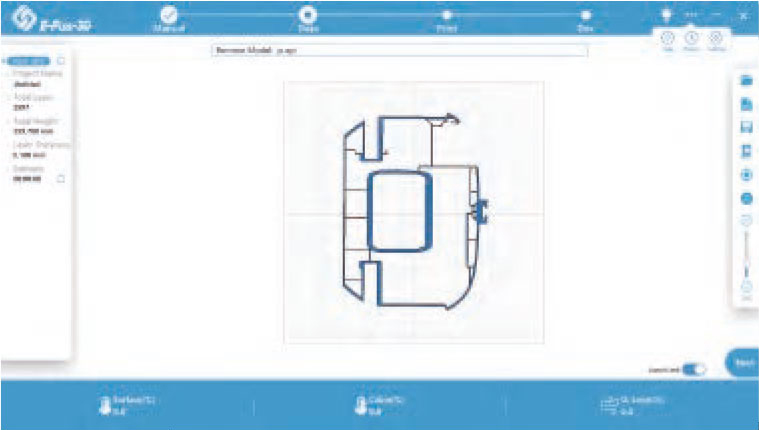

EPlus3D Steuersoftware

Die von Eplus3D entwickelte Steuersoftware repräsentiert ein leistungsstarkes Steuersystem. Mit einer offenen und benutzerfreundlichen Schnittstelle ermöglicht sie den Benutzern, ihre digitalen Dateien von der Bauvorbereitung und Teilepositionierung einfach zu steuern und bietet zudem die Möglichkeit zur Überwachung während des Bauprozesses samt Berichterstellung. Das kraftvolle Steuer- und Betriebssystem unterstützt nicht nur den Druck von ausgereiften Materialien, sondern auch die Entwicklung neuer Materialien.

Eplus3D EP-P420 Support und Service

- Professionelle Beratung

- Musterdruck Erstellung

- Individuelle Pakete für Industriekunden

- Einschulung vor Ort

- Individuelle Servicepakete

- Gesamtlösung mit geschlossener Entpulverstation

- Bauteiloptimierung via Fernwartung

- Materialversuche

- Prozessoptimierungen

- Kundenspezifische Seminare vor Ort

- Vor Ort Service

Downloads

Technische Daten

| Maschinenmodell | EP-P420 |

| Größe der Baukammer | 420 x 420 x 465 mm (L×B×H) |

| Gerätedimension | 2378 x 1394 x 2505 mm (L×B×H) |

| Materialien | PA11, PA12, PA6 und deren Verbundwerkstoffe |

| Maschinengewicht | 3.000 kg |

| Scan-Geschwindigkeit | Max. 15 m/s |

| Max. Kammertemperatur | 230 °C |

| Stromversorgung | AC 380 V, 15 KW, 50/60 Hz |

| Schichtdicke | 0,06 – 0,2 mm |

| Laserleistung | CO2 Laser, 120 W |

| Baugeschwindigkeit | 2500 cm3/h |

| Gasversorgung | N2 |

| Thermische Feldsteuerung | Unabhängiges Vierzonen-Temperaturregelungssystem |

| Temperaturregelung | Kontinuierliche Echtzeitüberwachung der Bautemperatur |

| Steuersoftware | Eplus3D Drucksoftware |

| Ausgabedatenformat | STL, OBJ, STEP oder andere konvertierbare Datei |