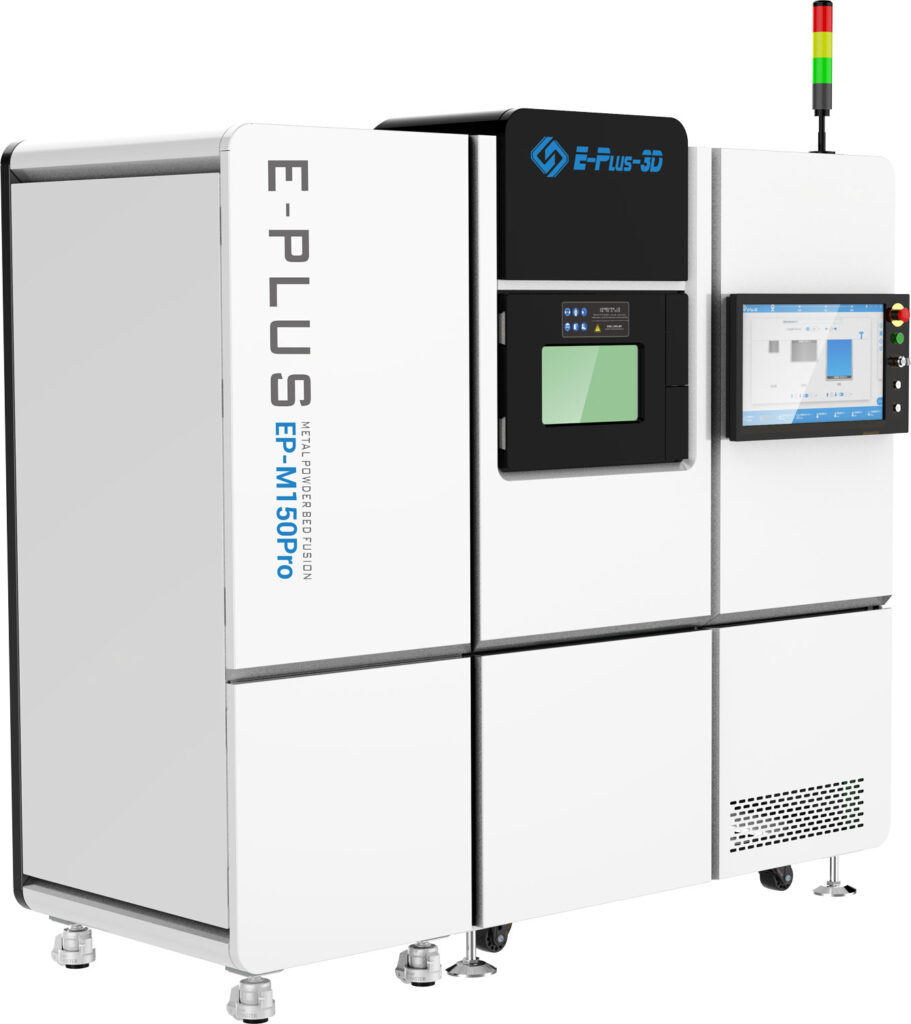

Eplus3D EP-M150 Pro

Metal Additive Manufacturing: hoch präzise & schnell

Medizin

Automobilindustrie

Luft- & Raumfahrt

Handelsgüter

Energie

Architektur

Prototypen

Hohe Effizienz

Mit unserer neuesten Technologie sind Schichtdicken von bis zu 100 μm möglich. Dank des Einsatzes von Dual-Laser und der Verwendung hoher Schichtdicken kann die Ausbringrate um beeindruckende 230 bis 270 % gesteigert werden.

5 – 35 cm³/h

Baugeschwindigkeit

20 μm – 100 μm

Schichtdicke

Ø 156 x 240 mm³

Druckvolumen

Hohe Präzision

Hohe Laserstrahlqualität, kleiner Laserspot und kontinuierliche und homogene Laserstrahlqualität an jeder Position im Bauraum.

Hohe Performance

Erreichbare Bauteildichte bei > 99,95%, Volatilität der mechanischen Eigenschaften < 5 % und Kalibriergenauigkeit im Laserüberlappungsbereich bei Dual-Laser < 30μm.

Offenheit

Hohe Wiederholgenauigkeit und gleichbleibende Parametersätze an mehreren Maschinen der EP-M Druckerfamilie. Kompatibel mit mehreren Materialien. Die Anlage kann unterschiedliche Metallpulver ohne Anpassung des optischen Pfads verarbeiten.

Bedienerfreundliches System

Ergonomisches Maschinendesign. Durch die O ne-Click-Printing Funktion ist die Maschine in kürzester Zeit Druckbereit. Die Vorbereitung der Anlage kann in wenigen Minuten durchgeführt werden.

Geringe Betriebskosten

Inertgasverbrauch während des Prozesses < 3 L/min. Automatisierte, regelbare Pulverzufuhr für hohe Materialeffizienz. Existierende Materialparametersätze werden kostenfrei zur Verfügung gestellt.

Sicherheit

Fehlbedienungssicheres Maschinen- und Softwaredesign. Durch entsprechende Filter und weitere Sicherheitsfaktoren kann wird die Bedienersicherheit erhöht. Die Echtzeitüberwachung des Prozessraums und der Umgebung sorgt für einen stabilen Prozess und eine hohe Reproduzierbarkeit.

Eplus3D Softwarelösungen

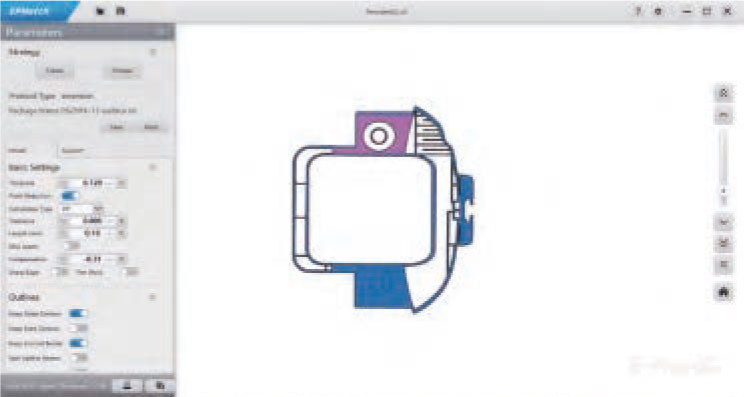

EP-Hatch Druckprozess-Planungssoftware

EP-Hatch ist eine von Eplus3D entwickelte Prozessplanungssoftware speziell für seine additiven Fertigungssysteme. Sie kann den Druckpfad basierend auf den bereits geschnittenen und ausgegebenen Daten optimieren und den Scanpfad separat für Kontur, Inneres, obere und untere Oberfläche des Teils einstellen. Darüber hinaus bietet EP-Hatch standardmäßig eine Vielzahl fortschrittlicher Scanstrategien wie lange gerade Linien, kurze gerade Linien, und Schachbrettmuster, die eine optimale Prozesseinstellung für spezifische Materialien ermöglichen.

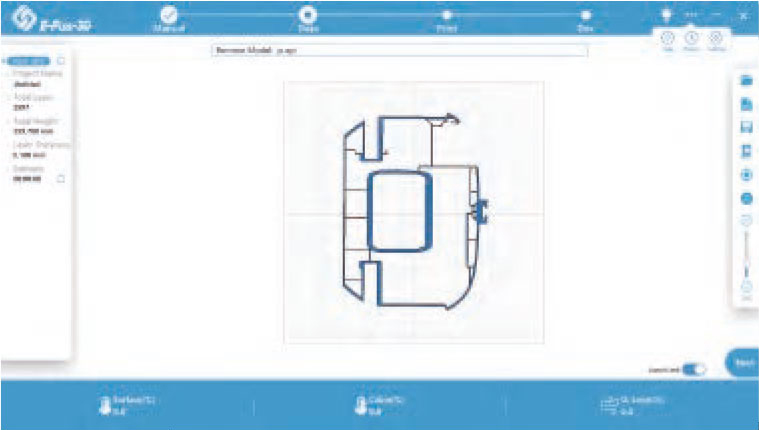

EPlus3D Steuersoftware

Die von Eplus3D entwickelte Steuersoftware repräsentiert ein leistungsstarkes Steuersystem. Mit einer offenen und benutzerfreundlichen Schnittstelle ermöglicht sie den Benutzern, ihre digitalen Dateien von der Bauvorbereitung und Teilepositionierung einfach zu steuern und bietet zudem die Möglichkeit zur Überwachung während des Bauprozesses samt Berichterstellung. Das kraftvolle Steuer- und Betriebssystem unterstützt nicht nur den Druck von ausgereiften Materialien, sondern auch die Entwicklung neuer Materialien.

Eplus3D EP-M150 Pro Support und Service

- Professionelle Beratung

- Musterdruck Erstellung

- Individuelle Pakete für Industriekunden

- Einschulung vor Ort

- Individuelle Servicepakete

- Gesamtlösung mit geschlossener Entpulverstation

- Bauteiloptimierung via Fernwartung

- Materialversuche

- Prozessoptimierungen

- Kundenspezifische Seminare vor Ort

- Vor Ort Service

Downloads

Technische Daten

| Maschinenmodell | EP-M150 Pro |

| Bauraum | Ø 156 x 240 mm³ |

| Optisches System | Faserlaser, 500 W (Single- oder Duallaser) |

| Laserspotgröße | 70 μm |

| Max. Scangeschwindigkeit | 8 m/s |

| Baugeschwindigkeit | Singlelaser: 5 – 20 cm³/h Duallaser: 8 – 35 cm³/h |

| Schichtdicke | 20 μm - 100 μm |

| Genauigkeit | Bis 100 mm Baugröße: < ±0,1 mm Ab 100 mm Baugröße: ± 0,1 % |

| Material | Titan-, Aluminium-, Nickelbasis, Cobalt-Chromlegierungen sowie Werkzeug- und Edelstähle, etc. |

| Stromversorgung | 380 V, 3P/N/PE, 12 KW, 23 A, 50~60 Hz (Duallaser: 13.5 KW, 28 A) |

| Gasversorgung | Ar/N2 |

| Sauerstoffgehalt in Prozesskammer | < 100 ppm |

| Dimensionen (L x B x H) | 2120 x 980 x 2250 mm³ |

| Gewicht | 1500 kg |

| Software | EP-Hatch, EP Control; weitere auf Anfrage |

| Format Eingangsdaten | STL oder andere konvertierbare Formate |