3DGence Industry F421

2-Kopf-3D-Drucker für anspruchsvolle industrielle Anwendungen.

Luft- & Raumfahrt

Architektur

Automobilindustrie

Handelsgüter

Bildungswesen

Medizin

Hohe Druckgeschwindigkeit

3DGence Industry F421 erweitert die Grenzen der Druckgeschwindigkeit industrieller 3D-Drucker.

Die Druckgeschwindigkeit ist der Schlüsselaspekt des Prozesses. Druckgeschwindigkeit bis zu 400 mm/s und 1 Meter pro Sekunde Fahrbewegung machen Industry F421 zu einem großartigen Werkzeug. Es ist eine großartige Maschine für Rapid Prototyping, aber auch ein vollwertiges additives Fertigungssystem für Ihr Unternehmen.

50 μm

Schichtauflösung

bis 500°C

Extruder Temperatur

bis zu 400 mm/s

Druckgeschwindigkeit

380 x 380 x 420 mm

Druckvolumen

M280

bis 280°C

Arbeitstemperatur

0,5 mm

Düsendurchmesser

Druckmaterial

PLA

ABS

ABS-ESD

ASA

PA6

PA-CF

Stützmaterial

ESM-10

HIPS

M360

bis 360°C

Arbeitstemperatur

0,4 mm

Düsendurchmesser

Druckmaterial

LEXAN

PC

PC-ABS

PEKK-CF

ULTEM 9085

Stützmaterial

ESM-10

M500

bis 500°C

Arbeitstemperatur

0,4 mm

Düsendurchmesser

Druckmaterial

PEEK

PEKK

VICTREX AM™ 200

Stützmaterial

ESM-10

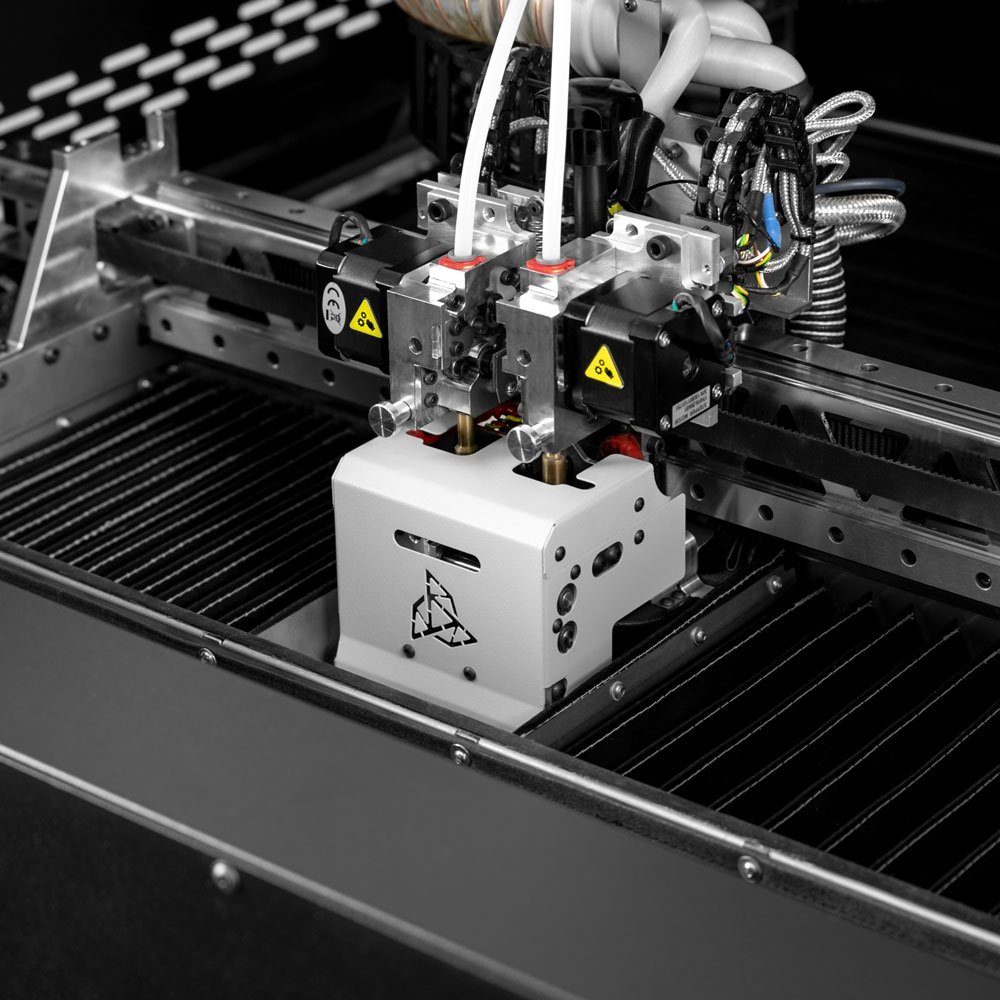

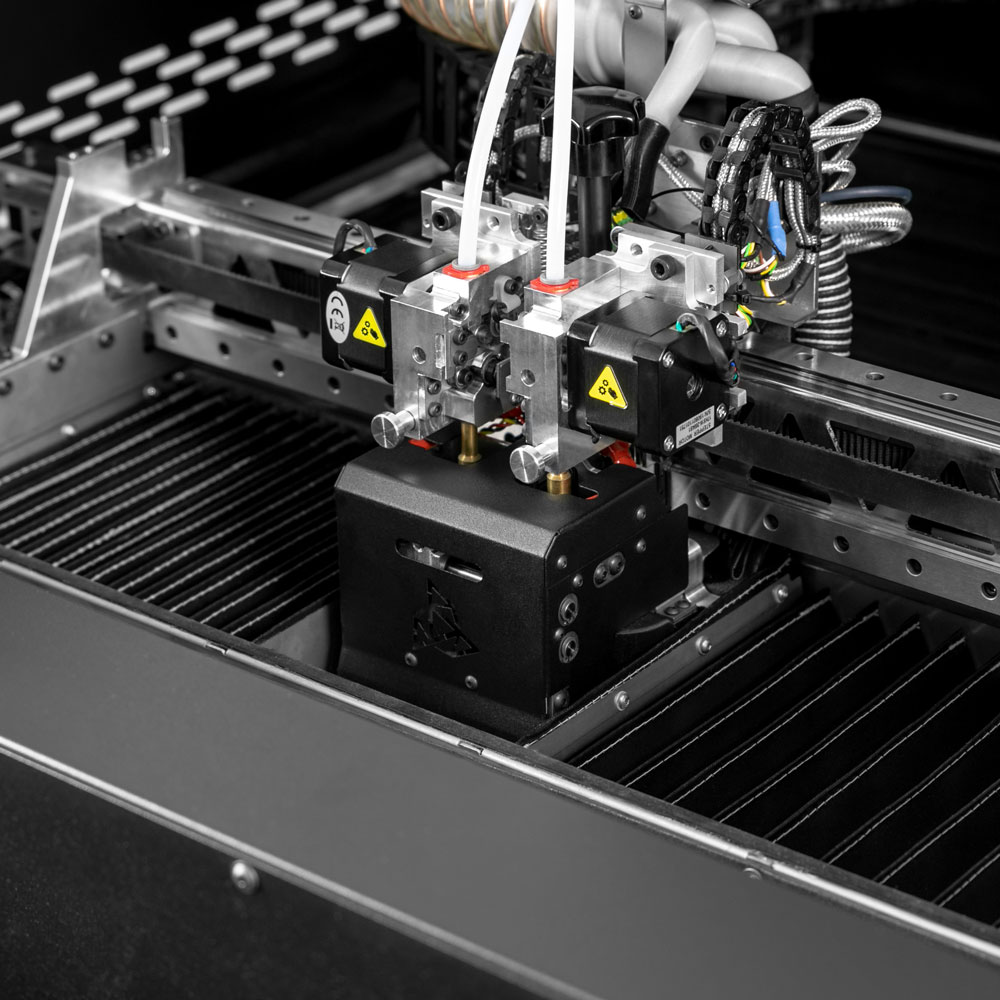

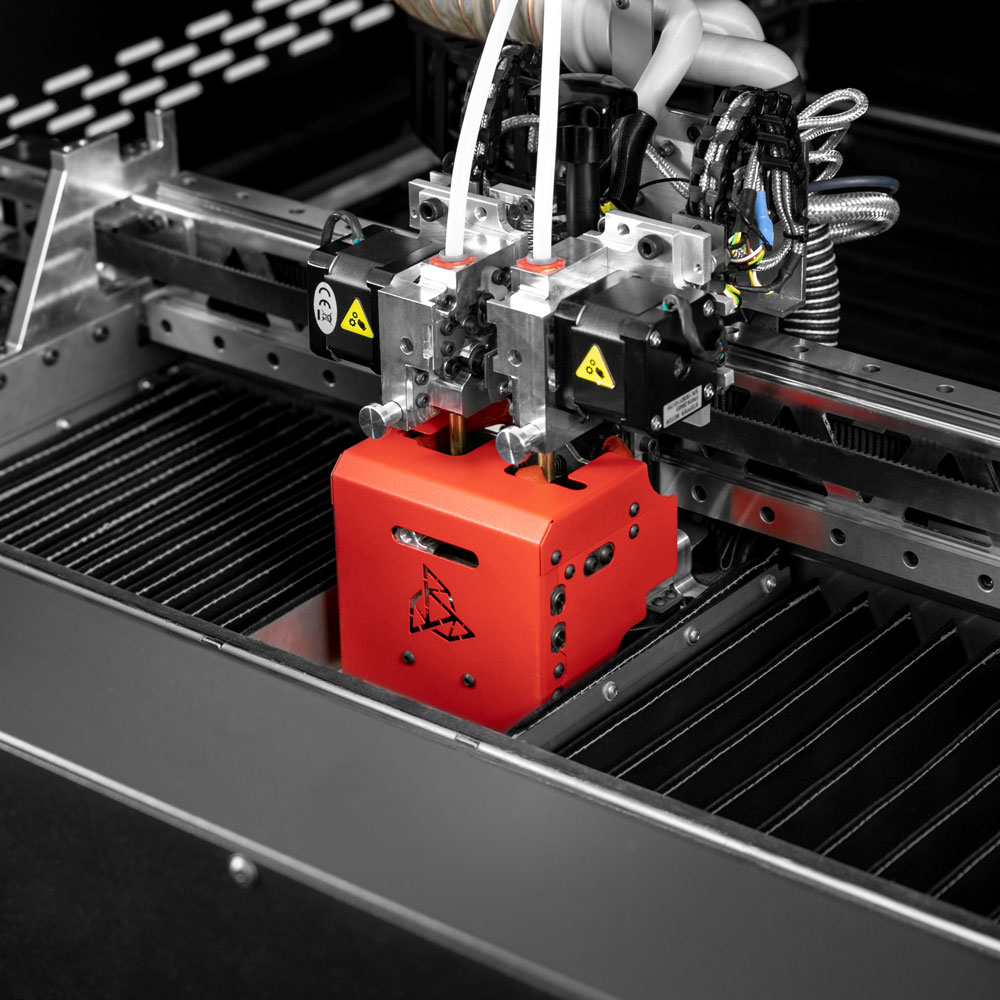

Austauschbare Druckmodule

Drucken von hochbeständigen und Ingenieur-Werkstoffen, die im breiten Temperaturbereich gedruckt werden können. 3DGence Industry F421 verfügt über ein modulares 3D-Druck-System. Der Benutzer braucht nicht mehr mehrere 3D-Drucker zu verwenden. Durch den Einsatz von für die jeweiligen Materialien konzipierten Modulen, die mit den vordefinierten Druckprofilen integriert sind, erzielt der Benutzer immer die beste Druckqualität.

Industrieller 3D-Drucker für Verbundwerkstoffe

Drucken Sie leistungsstarke Materialien, die zusätzlich verstärkt sind, um Ihre Endteile noch langlebiger zu machen. Jede 3DGence Industry F421 kann mit Hardware ausgestattet werden, die das sichere Drucken von verstärkten Materialien ermöglicht. Verbessern Sie die Produktion Ihrer am stärksten belasteten Bauteile.

Temperatur der Druckkammer sogar bis 180°C

Die erwärmte Kammer erlaubt hohe Temperaturen zu erzielen und diese stabil aufrechtzuerhalten. Die Materialien mit einer höheren Beständigkeit haben hohe Anforderungen an die Extrusion sowie die Temperaturen in der Kammer. Mittels der erwärmten Kammer können die hochbeständigen Ingenieur-Werkstoffe gedruckt werden, ohne dass dabei unzureichende Druckqualität bzw. irgendwelche Fehler befürchtet werden müssen.

Beheizte Materialkammer mit automatischem Spulenwechselsystem

Halten Sie Ihre Materialien immer trocken und druckbereit. Die Materialien werden dank der beheizten Materialkammer in einer stabilen Umgebung gehalten. In der Filamentkammer befinden sich 4 Materialschächte: zwei für Modellmaterialien und zwei für den Träger. Wenn das Material einer Spule ausgeht, wird es im Extruder automatisch durch das Material aus einer anderen Bucht ersetzt.

Sicherheit

Gewährleistung der Benutzersicherheit und der Kontinuität des technologischen Prozesses. Das Filtrationssystem des Industry F421 bietet die extrem gute Filtrationsleistung, die bei in der FFF-Technologie betriebenen Druckern nicht anzutreffen ist. Die fortgeschrittene dreistufige Filtrationseinheit hält Makropartikeln, Nanopartikeln (VOC, UFP), Lösungsmitteldämpfe oder schädliche Gase zurück.

Smart Material Manager

Garantie optimaler Arbeitsbedingungen. Der NFC-Scanner sammelt Daten, die mit dem während des Druckvorgangs verwendeten Filament verbunden sind – optimale Arbeitsbedingungen und maximale Geschwindigkeit. Alle Informationen zu Gewicht, Typ, Farbe und prozentualer Menge des verbleibenden Filaments, das an einem bestimmten Hotend geladen ist.

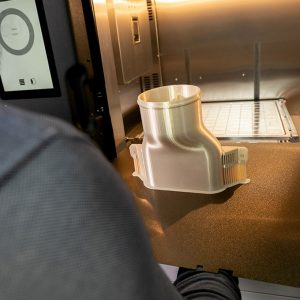

Großes Volumen der Druckkammer

Das Volumen der Kammer erlaubt das Drucken großer Modelle in einem Ablauf.

Aufgrund der Abmessungen von 380 x 380 x 420 mm kann der Drucker auch die größeren 3D-Modelle drucken, ohne dass das Modell geteilt und nachträglich wieder zusammengebaut werden muss.

Das in 3DGence Industry F421 verwendete Tensometriesystem ermöglicht außerdem die automatische Kalibrierung dieses 3D-Druckers.

Materialien für 3DGence Industry F421

PA6 Low Warp CF15S™

3DGence Industry F421 Webinar

Damit Sie mit Ihrem neuen 3D-Drucker schnell produktiv arbeiten können, bieten wir Ihnen unseren Schnellstart-Kurs in Form eines Webinars (Web-basiertes Seminar) an: Nach 120 Minuten verstehen Sie die Funktionsweise der 3D-Drucksoftware.

Ablauf des Webinars

- Einführung in die Funktionsweise und Bedienung der 3D-Drucksoftware

- Überblick über die Bedeutung der Einstellungen

- Die richtigen Einstellungen für Ihren perfekten 3D Ausdruck!

- Tipps & Tricks

- Trouble Shooting – Ursachen und Lösungen für die häufigsten Probleme

Voraussetzungen

- Vorhandener, einsatzbereiter PC mit Windows 7, 8 oder Mac OS X mit vollen Administrator-Rechten

- Internetzugang

- Bereits installierte und funktionsbereite TeamViewer oder Microsoft Teams Software

Die Details zum Termin und der Webinar-Software werden nach Eingang Ihrer Bestellung abgesprochen.

Support und Service

- Professionelle Beratung

- Musterdruck Erstellung

- Individuelle Pakete für Industriekunden

- Einschulung vor Ort

- Servicepaket mit kostenlosem Telefon- und Email Support

- Gesamtlösung mit Waschstation

- Bauteiloptimierung via Fernwartung

- Materialversuche

- Prozessoptimierungen

- Kundenspezifische Seminare vor Ort

- Vor Ort Service

Downloads

Technische Daten

| 3D-Drucktechnologie | FFF |

| Arbeitsraum | 380 x 380 x 420 mm (60 648 cm3) |

| Drucksystem | 2, Druckkopf-Reinigungssystem |

| Düsendurchmesser | 0.5/0.5 mm, 0.4/0.4mm |

| Durchmesser des Filamentes/ Filament-Kammer | 1.75 mm / 4 Plätze |

| Modellmaterialien | PLA, ABS, ABS-ESD, ASA, PA6, PA-CF, LEXAN, PC, PC-ABS, PEKK-CF, ULTEM 9085, PEEK, PEKK, VICTREX AM™ 200 |

| Stützmaterial | Abbrechbare Stützmaterialien, lösliches ESM- 10 Stützmaterial. |

| Temperatur des Druckkopfes (max.): | 500°C |

| Temperatur des Druckbettes (max.) | 180°C |

| Temperatur der Arbeitskammer (max.) | 180°C (aktive Heizung) |

| Temperatur der Filamentkammer (max.) | 50°C |

| Software | 3D-Gence SLICER 4.0, 3D-Gence CLOUD |

| Optionales Zubehör | Fortgeschrittene ULT-Filtrationseinheit, Türöffnungssensoren, Oberdeckelöffnungssensoren, Temperatursensoren, NOT-SchalterUPS /Notstromversorgung, Wartungsvertrag |